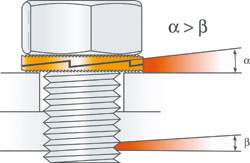

If you’re looking to ensure fasteners don’t work their way loose in a high vibration environment, the washers from Nord-Lock are worth considering. The basic premise behind them is to use ramps (at an angle greater than the pitch) to increase the bolt tension as the bolt begins to loosen – and thus ensure that the bolt will not be able to loosen. The video on their website does a good job of explaining this in more detail and comparing it to other popular locking methods.

If you’re looking to ensure fasteners don’t work their way loose in a high vibration environment, the washers from Nord-Lock are worth considering. The basic premise behind them is to use ramps (at an angle greater than the pitch) to increase the bolt tension as the bolt begins to loosen – and thus ensure that the bolt will not be able to loosen. The video on their website does a good job of explaining this in more detail and comparing it to other popular locking methods.

Category Archives: Design

New issue of Lotus proActive newsletter

The May/June 2007 issue of the free Lotus proActive newsletter is available for download here. This issue covers various news from Lotus and the automotive industry in general, the advantages of reducing vehicle structure weight (and how to go about it), the robot-piloted Elise used in an upcoming DARPA competition, CO2 emissions reduction.

The May/June 2007 issue of the free Lotus proActive newsletter is available for download here. This issue covers various news from Lotus and the automotive industry in general, the advantages of reducing vehicle structure weight (and how to go about it), the robot-piloted Elise used in an upcoming DARPA competition, CO2 emissions reduction.

One thing about their chassis design though, is that while using various cold joining techniques such as adhesive may be nice from a design perspective as you don’t have Heat Affected Zones of decreased strength around welded joints, this design approach fails to address how the vehicle may someday be repaired if necessary. Designing around Heat Affected Joints may lead to increased overall weight of the vehicle, but the alternative leaves little ability to rework a damaged chassis. The result can be viewed with Lotus’ current sports car, the Elise. There exists no approved method for repairing an Elise chassis, as it’s created entirely through cold joining techniques. While it is technologically feasible to repair a chassis by adding sufficient reinforcement to compensate for Heat Affected Joints necessitated by common repair techniques (ie, welding), there is no set formula for how to do this. The result is if the chassis suffers any damage whatsoever, replacement is the only option. This trend may be of little importance to the automobile manufacturer, as it’s a cost incurred by the customer, not them. However, if this attitude continues then increasing insurance costs will lead to savvy consumers avoiding cars designed in this manner. A good design will strike a balance not just in manufacturing and performance, but over the expected life of the product. A reality of that, for a car, is that the vehicle may experience a minor accident such that the car should not need to be totaled. Again, as an example, a minor accident in an Elise that impacts one of the wheels can often deform the suspension mounting points on the chassis – which then necessitates replacement of the entire chassis! Keep this in mind while reading about all the advantages of Lotus’ VVT vehicle architecture – it may sound good, but how will it be repaired? This is a good lesson for engineering design in general; we often get tunnel-vision and fail to consider the larger picture of how the product will actually be used (and abused!).

Liquid Cooling for Computers

You’ve probably heard of them already, but in case you haven’t, Thermaltake has a great selection of DIY components for liquid cooling of computers and similar products. They offer both passive and active radiator solutions, plus various ways to cool CPUs, memory, video cards, etc. Pretty extensive. It does seem geared more towards the DIY rather than OEM; if you’re designing such a system for an OEM I recommend you also check out CoolIT; they have some very high quality products and are a good fit for production systems (Thermaltake may be as well, I just haven’t seen their products up close yet).

You’ve probably heard of them already, but in case you haven’t, Thermaltake has a great selection of DIY components for liquid cooling of computers and similar products. They offer both passive and active radiator solutions, plus various ways to cool CPUs, memory, video cards, etc. Pretty extensive. It does seem geared more towards the DIY rather than OEM; if you’re designing such a system for an OEM I recommend you also check out CoolIT; they have some very high quality products and are a good fit for production systems (Thermaltake may be as well, I just haven’t seen their products up close yet).

Don’t screw it in, SNAP it in instead!

A German company, Dirak, has taken an unusual approach to sheetmetal assembly. They’ve worked out a system for literally snapping components in place rather than using screws. This system is being used on everything from latches to handles and even hinges. The advantages are fairly obvious, mainly, lower assembly cost. However, this will be offset somewhat by an expected higher unit cost. Still, it’s an interesting approach. Check it out here. (via Design News)

A German company, Dirak, has taken an unusual approach to sheetmetal assembly. They’ve worked out a system for literally snapping components in place rather than using screws. This system is being used on everything from latches to handles and even hinges. The advantages are fairly obvious, mainly, lower assembly cost. However, this will be offset somewhat by an expected higher unit cost. Still, it’s an interesting approach. Check it out here. (via Design News)